Innovation is a key factor in the field of electronics. As the demands for smaller, more flexible, and superior-performing electronic devices continue to grow manufacturers are always looking for new ways to revolutionize the process of assembly. Production of flexible circuits is one of the most innovative technology that has received an enormous amount of attention.

Flex circuits, often referred to as flexible printed circuit boards (PCBs), offer many advantages over rigid PCBs. They are extremely flexible designed to bend, twitch and conform to various forms. This makes them suitable for applications which require intricate designs or have space limitations in addition to increased durability.

Flex circuits can be a method manufacturers can push the boundaries in design. They offer flexible components that adapt to product contours. Flexibility allows for more imaginative and compact design, ultimately leading to lighter and smaller devices. Imagine a smartphone that seamlessly wraps around your wrist. Wearable health monitor that fits discreetly around the wrist. It’s even a smart gadget with a seamless and ergonomic design. Flexible circuits allow engineers and designers to turn these ideas into reality, opening up an entirely new realm of possibilities for product development.

Beyond the aesthetic advantages, the durability of flex circuits makes them stand apart from their rigid counterparts. Traditional PCBs are prone to damage from vibration, shock and continual bending. Flexible circuits are built using specially designed materials that are able to withstand these problems. They’re therefore highly robust even in the most challenging environments. This is particularly important in industries like aerospace automobile and medical in which electronic components are exposed to extreme conditions.

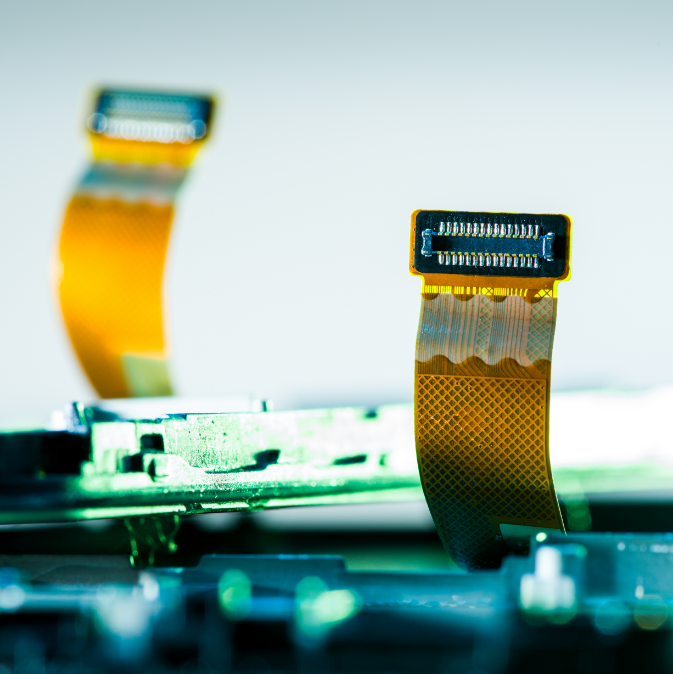

The manufacturing methods employed in the production of flex circuits contribute to their remarkable capabilities. Contrary to rigid PCBs, which are made of multiple layers of fiberglass or copper, flex circuits are constructed by using a thin and flexible substrate material such as polyimide and polyester. This substrate acts as the foundation for the circuit and allows it to stretch and bend and maintain electrical connectivity. Flexible circuit makers are able to precisely cut circuit trace, join complex interconnects and attach components to the flexible substrate through the use of modern manufacturing techniques.

The ability to integrate components directly into the flex circuit called surface mount technology (SMT) can further increase the functionality and flexibility of these circuits. SMT permits manufacturers to place electronic components directly on the surface of the device that is a flex circuit. This removes the need for bulky connectors, and reduces the size of the circuit. This method of streamlined design not only improves signal integrity, it also decreases weight and improves thermal control.

The flex circuit production techniques also allow for rapid prototyping, and can be scaled to meet the requirements of larger quantities. Flexible circuit designs enable rapid iterations in the prototyping stage, which accelerates the process of developing a product. Additionally, because flexible circuits can be manufactured in large quantities by automated manufacturing processes, they are cost-effective solutions for high-volume production. This makes flex circuits an ideal choice for companies looking to get their new ideas to market quickly. For more information, click flex circuit manufacturing

As the demand for flexible electronics continues to increase and grow, having reliable manufacturers of flex circuits becomes crucial. It is imperative to work with trusted, seasoned manufacturers to ensure the accuracy and reliability in the manufacturing of flex circuits. They are able offer guidance and insights regarding the design and manufacturing process. They can also give suggestions on the selection of materials.

Ultimately, flex circuits are essential components to achieve the most complex level in modern electronic assemblies. Flex circuits play an important function in the design of sophisticated electronic systems. From consumer electronic devices to military equipment, they are employed in a wide range of applications. Because they can move easily through compact areas, flexible substrates offer engineers the ability to make their designs feature-rich but still fit within small footprints for assembly. While it’s true that there are a variety of other forms of circuit routing are available however their electrical and mechanical characteristics aren’t as impressive as those provided by flexible assembly solutions for complying with strict size limits. Flex circuits are the best suitable option for projects that require complex interconnections that incorporate multiple technologies in an organized package.